Demands of the steel industry

Work rolls for skin passing mill

- Characteristic and properties of roll texture

- Cost-efficient process for texturing work rolls

- Lifetime of textured work rolls in production

- schedule free rolling

Texturing of metal sheet

Advantages for the skin passing process

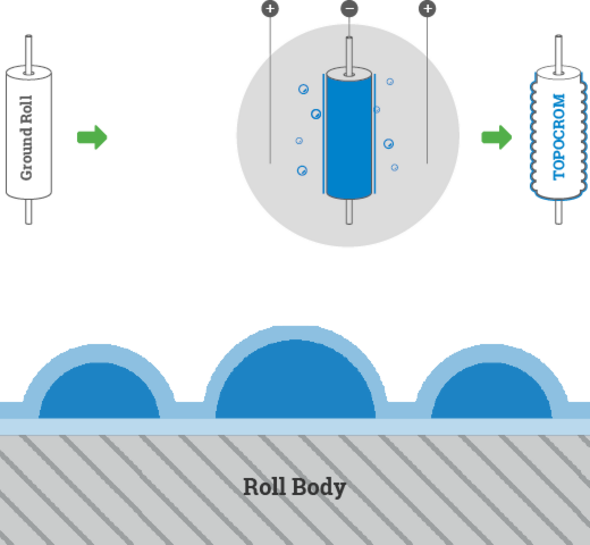

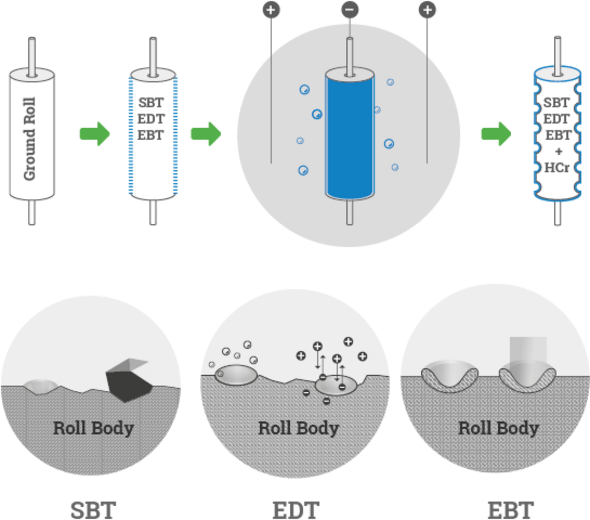

The TOPOCROM® textured metal sheet surface shows stochastically distributed cavities transferred by the skin pass roll. This sheet surface is especially characterized by variable surface topographies.

Advantages of TOPOCROM® textured metal sheet:

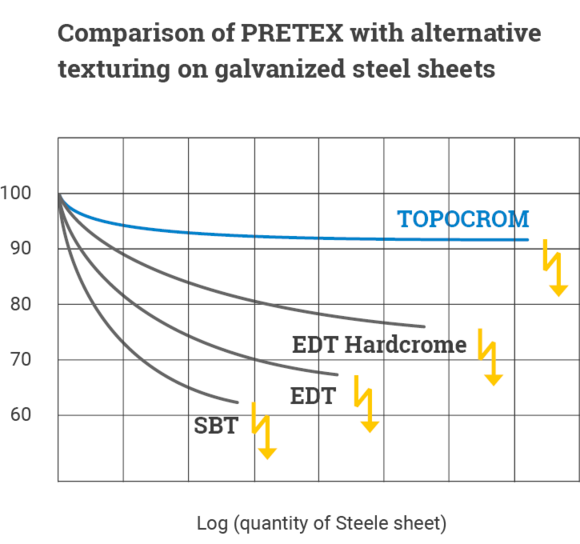

- long service life of work rolls

- high variability of the metal sheet structure

- Excellent painting and forming behaviour

- low long and short waviness

Work rolls

Quality and service life

- Very low Roughness Decrease and therefore long Life Time due to Hemispherical Surface Structure, Multilayer Design and due to the Hardness of Hard Chromium Coatings

- 3 - 5 times longer Life Time compared to EDT Rolls (+ hard chromium plated)

- Constant Product Quality with TOPOCROM Rolls from the beginning (no running in-time) High pressure cleaning of working rolls during operation is necessary

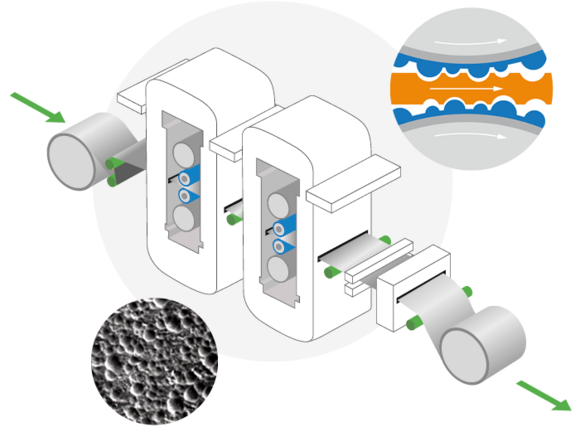

Schedule Free Rolling

with TOPOCROM® rolls

In applications with many roll changes, schedule free rolling is possible.

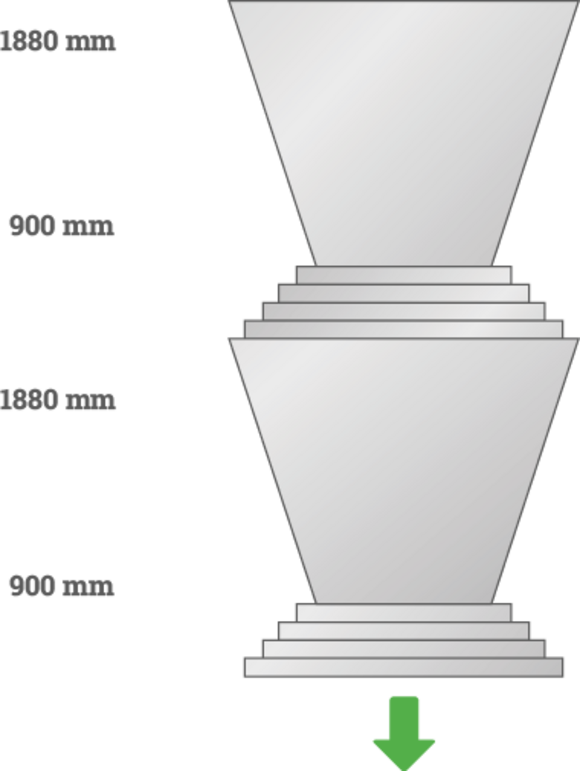

technical data:

- width: 1880 – 900 mm

- thickness: 2,0 – 0,35 mm

- max. skin-pass speed: 175 n/min

- wet skin pass only

- inline roll cleaning

- high pressure 200 bar

work roll performance:

- 6.000 to (high-strenght steele)

- 30.000 to (normal qualities)