Construction

Topocrom Plant System

Topocrom Plant System is a special Process Technology for Electroplating of Hard Chromium Coatings with a typical hemispherical Surface Structure.

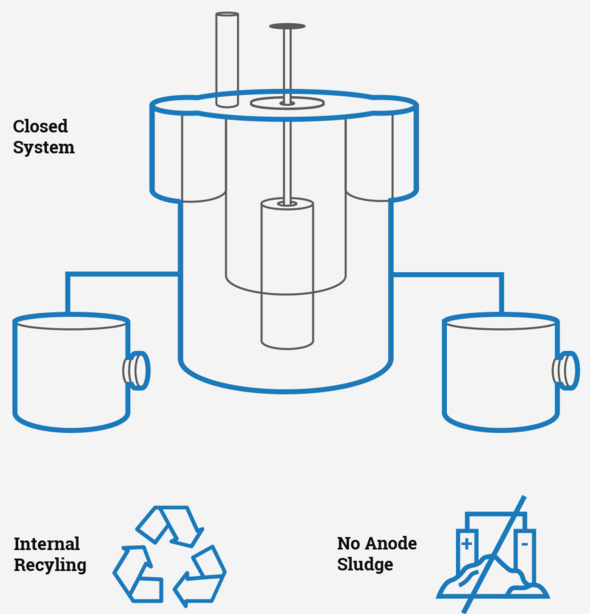

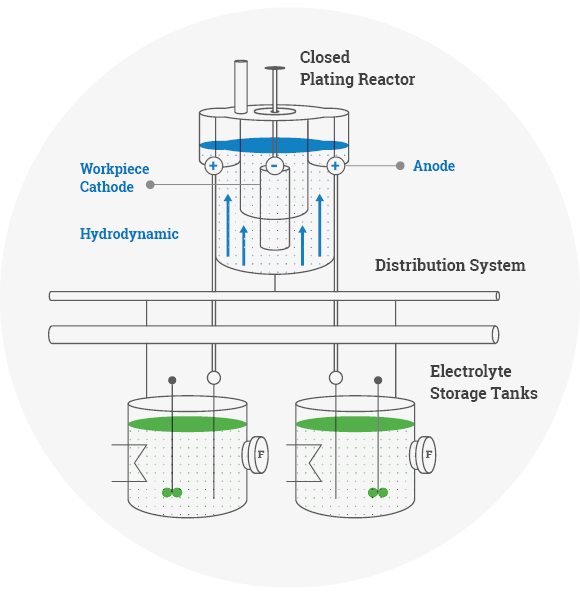

The reactor is the closed electroplating cell for the hard chromium plating process. The electrolytes are stored in closed electrolyte storage tanks (working container) Work rolls to be plated are inserted into the empty reactor and connected with the power source. Then the reactor is closed. During the plating process the electrolyte circulates continuously between electrolyte tank and reactor. After the plating process is finished the electrolyte is pumped back to the tank. The reactor is empty when unloaded.

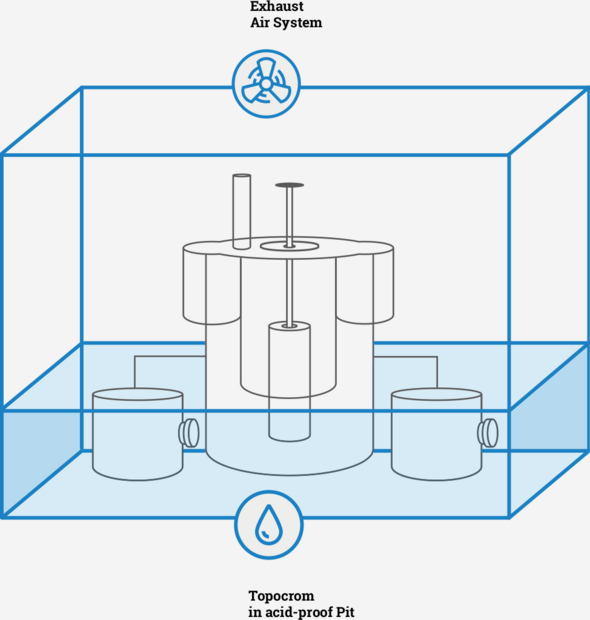

The Topocrom® plant is installed in an acid-proof concrete pit. The closed loop design in combination with the exhaust air cleaning system constitutes the highest standard in protecting environment and staff from being exposed to electrolyte fumes.

1. Stand-by tank

2. Rectifier

3. Plating reactors

4. Topocrom electrolyte tank

5. Exhaust air system

6. Electrolyte tank for base and top layer

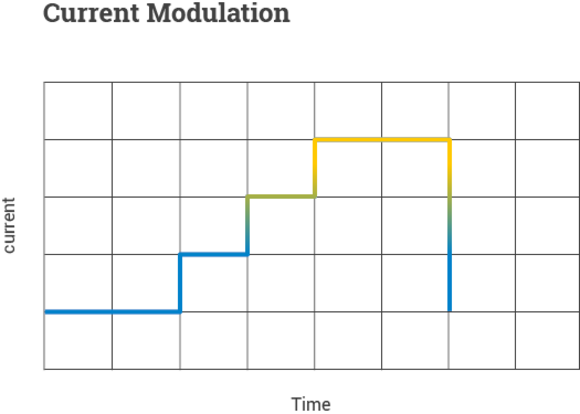

Topocrom Process Parameter

Physically adjustable

Current, temperature and time are precisely adjustable